So, if you are going to develop your HP5+ at 23 degrees C/73.5 degrees C, you will find 7:15 – 7 minutes and 15 seconds. Find “O” in the first column (“CHART LETTER”) and you can read off from that row all the different development times for the different temperatures at the heads of the columns. If your working temperature is not on this chart, simply note the letter next to your film (for HP5+ that would be “O”), and go to Sprint’s Development Timing System Chart (here). With experience, you may want to make your own adjustments. For example, for Ilford HP5+ at 75 degrees F/24 degrees C we recommend 6:30 – that is 6 minutes 30 seconds. To find the recommended development time for your film, find it on the STANDARD Film Developer Time Chart, and read across to the column with your working temperature at the top. You can develop any films with the same chart letter together in the same tank. *In very dry conditions, desert or a heated building in very cold weather, all solutions will tend to evaporate faster than usual, which may cause a degree or two of unexpected cooling.ĭifferent films develop at different speeds Sprint’s Chart Letter summarizes this information and gives you a convenient way to find the appropriate developing time at your room temperature. Sprint tries to make things easy for you – within limits you can process film at room temperature – the temperature at which everything tends to end up anyway* – and adjust developing time according to our chart, rather than struggling to maintain exactly 20 or 24 degrees Celsius. While experience – and keeping good notes on what you did – is the best teacher, Sprint’s Standard Film Developer Time Chart (here) will give a good starting point.

DOES THE AMOUNT OF STOP BATH USED AFFECT THE FINAL PRINT FULL

For a rich, easily printed, full gradation image, you have to get it right. Develop long enough and hot enough, and your film will all but turn a solid black too short a time and too cold will hardly give you anything. The warmer the developer, the faster it acts, while cool temperatures slow things down. Time, and temperature (- and agitation – more on that later – ) are very important in film developing. Procedures for Processing B&W Negative Films = 1000ml STANDARD B&W Film Developer Working Solution Directions provided here are for basic negative processing, using the developer once only.ġ00ml STANDARD B&W Film Developer Concentrate

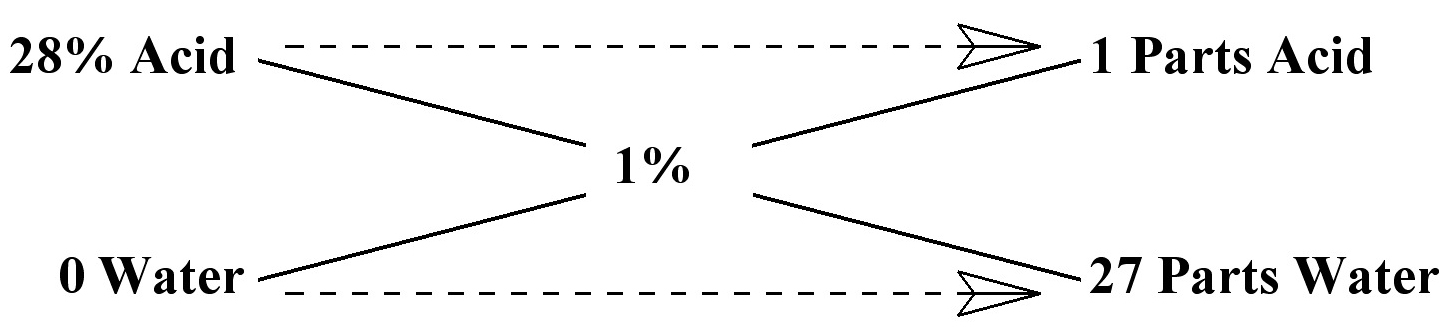

One liter of STANDARD concentrate will make 10 liters of working solution, enough to develop at least (50) rolls of 35mm 36 exposure film, (or enough replenished solution to develop 110 rolls). In other words, if you are going to develop 4 rolls of 35mm film in a typical stainless-steel tank, which holds 1 liter, you will need to combine 100 ml of concentrate with 900 ml of water. You dilute it 1:9 with water, to make a working solution.

Web: com )/RD/Type/Annot/AP>endobj19 0 obj/Font/ProcSet>endobj20 0 objstream.

0 kommentar(er)

0 kommentar(er)